Wooden block pressing machine will lower down your production cost and reduce negative impact on environment

From environmental and from economic perspective we are all striving to make less or no negative impact to the eco system as well as trying to do our best from economic perspective. Almost in all industries there is a demand for pallets, either for internal transport or for transport in general. Transport pallets are made from wooden boards and from wooden blocks. Up to recently wooden blocks would of been only made out of solid timber. Obviusly this is not most environmently friendly as we need to cutt the trees to make raw material available.

As in the timber industry there is always enough sawing dust available and with recycling of old pallets there is always enough wooden chips available, there became idea to start making wooden blocks for pallets out of saw dust & wooden chips or lets say from waste.

This is how complete production line for wooden block pallets became reality. Wooden block are made now out of saw dust and/or wooden chips. For all of you pallet manufacturers this is a big advantage. This i a great fit to existing pallet production line.

The production process of wooden pallet blocks is as follows:

- Sawdust stored in a silo is transported to the mixer using a screw feeder.1. The wood chip particles must be up to 20mm in size. If the particles are larger, issues with the homogeneity of the blocks occur, and the blocks fail the EPAL certification test. We offer a wood crusher and a wood mill.

2. The moisture content of the sawdust must not exceed 10%. We offer a sawdust drying line (gas or biomass powered).

- A special adhesive is prepared in the mixer, which is an integral part of the line, and is dosed through nozzles into the sawdust mixer.

- The adhesive content is 15% of the mass. We have developed a special adhesive for the production of pallet blocks that meets EU safety and environmental standards. Delivery of adhesive throughout the EU is possible.

- With the help of a hydraulic drive, the mixture of adhesive and sawdust is extruded/pressed into molds.

- The molds must be heated to a temperature between 120°C and 140°C to ensure that the adhesive has fully reacted.

- At the end of the press, an automatic saw cuts the blocks to a length of 1000mm–1200mm.

- A separate saw is used to cut the blocks into the required cube dimensions. Standard dimensions of wooden cubes for EUR pallets are 100x100x78mm and 100x145x78mm. Molds of different sizes can be ordered for other cube dimensions.

- At the end of the process, a robot picks up the cubes and stacks them on a pallet (optional; the line can also be ordered without the palletizing robot).

- The capacity of a single block pressing machine is up to 9m³ of cubes per 24 hours. Multiple pressing machines can be operated in parallel.

- The quality of the pallet blocks is suitable for EPAL certification.

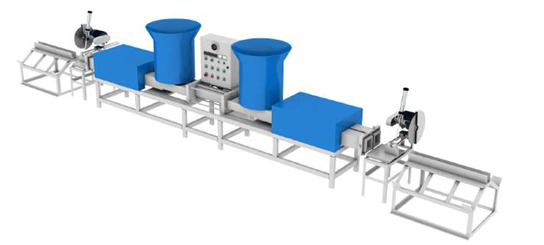

The production line for wooden pallet blocks consists of:

- Wood crusher and mill (optional)

- Sawdust dryer (optional)

- Silo for sawdust and wood chips (optional)

- Sawdust and adhesive mixer

- Adhesive preparation system with mixer (optional if powdered adhesive is used)

- Hydraulic press for pressing sawdust

- Automatic saw for cutting blocks to the final size

- Palletizing robot

- PLC and HMI control in multiple languages

If you are in a need for this type of machine do not hestitate to contact us.

Beside this we are able to support you in any other industrial automation, robotics or special machine building.